Dough Conditioner

Over 20 years of know-how about research

and development has created

a unique Invertor Dough Conditioner of SOFTMILL.

LED touch screen, moisture care system,

high efficiency refrigeration compressor,

PID proportional control system,

air circulation internal structure

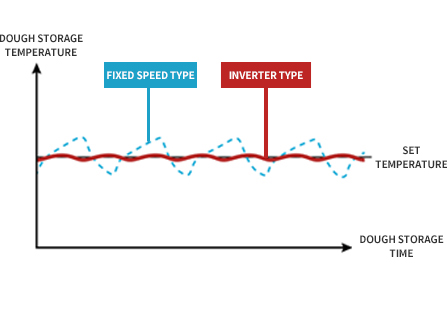

Product Comparison

Inverter Inverter Dough Conditioner

- Korea's First Inverter Dough Conditioner

- Upgraded from the fixed speed motor to a speed-controlled BLCD Inverter motor.

※The BLCD inverter motor is a motor that provides precise speed control compared to the normal motor.

- Save 40% on electrical charges

- The use of inverter motors has reduced power usage and electricity charges by 40% compared to its previous model.

- Top-of-the-line temperature keeping function

- Maintain the set temperature with a deviation of less than 0.5 degrees.

- Use of High Insulation and eco-friendly urethane with appropriate KS standard.

- Uses HFC-FREE urethane as insulation material in product to a thickness of 6T.

Details

Douch Conditioner

- LCD Touch Screen

- It is available to use the machine smartly,

easily at the checking operation status,

setting the temperature and humidity(First time in Korea)

- Moisture Care System

- Moisture care system which carry out the enough moisture supply through 4 steps fermentation processes(freezer – defrost - low temperature fermentation - high temperature fermentation) maintains the dough’s optimal conditions.

- High Efficient Compressor

- You can cut down the electric bills charge 10% comparing with normal model.

- PWM Proportional Control System

- keeps the optimal temperature and humidity by its number of smart sensor and micro processor.

- Inside’s Air Circulation Structure

- Cold air is not directly reached to the dough. That is feasible from our unique air circulation structure. So dough can be remained keeping humidity

You can optimize your baking process with Softmill’s Dough Conditioner

You set the program for the baking time of the following day;the dough conditioner will automatically process the following 4 steps automatically: freezing → unfreezing → cold fermentation → warm fermentation.

Plus, when it comes to the freezing, our very own hydration system and digital temperature-humidity sensor will provide humidity at low temperature to prevent the doughs from drying and to take a delicate care of them.

Dough Conditioner: a Use Case

Frozen Dough

Frozen Dough- 19:00Temperature -5˚C

/ Humidity - - 24:00Temperature 2 ° C

/ Humidity 75% - 04:00Temperature 15 ° C

/ Humidity 75% - 05:00Temperature 35 ° C

/ Humidity 85% - 06:00Fermentation

completed  Fermented Dough

Fermented Dough

- Freezing

Fermentation ceased

for maximum 3 days - Unfreezing

Low temperature,

high humidity - Cold Fermentation

- Warm Fermentation

- Baking

Dough Conditioner’s Function

Inside a Dough Conditioner

Inside a Dough Conditioner

With our own convection and hydration technology our dough conditioners can keep the low temperature and high humidity precisely.

With our own convection method our dough conditioners can prevent doughs from getting dry and keep the inside temperature and humidity even. Our fans are made specially to endure the high temperature and high humidity condition, so that they can be used for a long term.

You can keep the low temperature

and high humidity automatically. Low temperature high humidity unfreezing mode uses digital temperature-humidity sensor

and our own humidifying method to precisely keep the inside temperature

as 2ºC and humidity as 75%. You can also freeing set the humidity from 60% to 90% as well.

and high humidity automatically. Low temperature high humidity unfreezing mode uses digital temperature-humidity sensor

and our own humidifying method to precisely keep the inside temperature

as 2ºC and humidity as 75%. You can also freeing set the humidity from 60% to 90% as well.

Low temperature high humidity unfreezing mode progress display

Low temperature high humidity unfreezing mode progress display

.jpg)

.jpg)

.jpg)